Commercial and Residential

Repair and Maintenance

Inspection and Testing

Decommissioning

Elevator Diagnostics 101: Decoding Common Issues and Solutions

Approximately 10,000 elevator-related injuries occur each year, emphasizing the need for proper elevator maintenance in your commercial business. Any minor issue can lead to downtime, business interruptions, and potential accidents. These can have severe consequences, such as increased operating costs, potential litigation, and a depreciated business reputation.

In these circumstances, elevator diagnostics are vital. The ability to identify and mitigate common elevator complications aids in averting most mechanical failures, ensuring your elevator operates at peak efficiency.

This preventive strategy leads to safer operations, enhanced usability, and reduced long-term costs. To glean further insights on this, continue reading about common elevator problems to be vigilant for.

Mechanical Failure

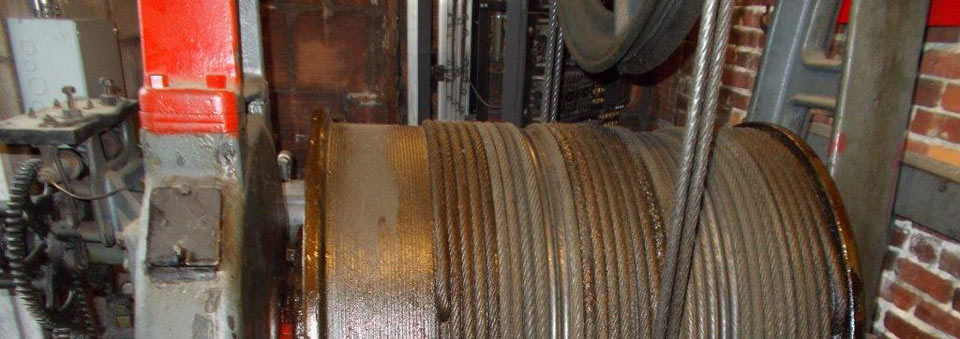

A leading cause of elevator injuries is mechanical failure. Such problems arise from issues like worn sheaves, which put a strain on the ropes and cause them to wear down. If you notice sudden jerking movements or changes in speed, this might be the root cause.

Yet there’s a solution. Regular maintenance can mitigate this. Having a professional routinely service the elevator can prevent significant issues down the line.

Inaccurate Elevator Leveling

In some cases, the elevator may not stop evenly with the floor, leading to potential tripping hazards. This issue is often associated with faulty elevator sensors.

Once these sensors fail, the elevator carriage may not stop as required. This disrupts the seamless movement of passengers in and out of the elevator.

Resolving this issue entails replacing the faulty sensors. Once calibrated, the new sensors should improve the precision of elevator stops.

Misaligned Doors

Misaligned doors constitute another common problem. This happens when there’s uneven wear and tear on the door equipment, causing the elevator doors to malfunction.

It’s vital not to ignore these issues. Misaligned doors can lead to further complications and pose a safety hazard to users. The likely solution here is an elevator repair that realigns the doors.

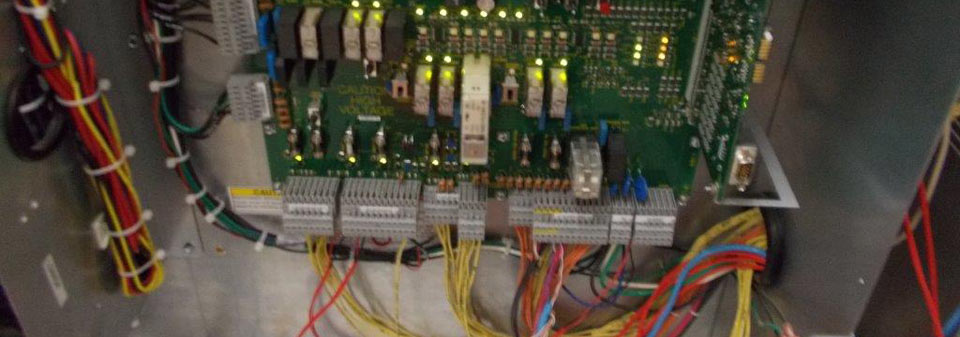

Electrical System Malfunctions

If your elevator experiences unexpected shutdowns or erratic operations, it could indicate electrical issues. Approaching a professional to diagnose and rectify electrical problems is the best way forward. After a thorough repair, sign up for regular maintenance to stop the problem from reoccurring.

The Importance of Regular Maintenance

Regular maintenance is your golden key to elevator longevity and efficient performance. Consider setting a maintenance schedule that includes professional inspections of all the elevator’s components, including the cables, safety system, and door mechanisms. The frequency of maintenance would depend on various factors, including the lift’s age, usage, and manufacturer’s recommendations.

Ensure Safety With Professional Elevator Diagnostics

The importance of effective elevator diagnostics cannot be overstated. We’ve expounded on several common issues and their implications, such as mechanical failures, misaligned doors, inaccurate leveling, and electrical system malfunctions.

You can prevent and rectify these crucial issues through regular professional maintenance. Routine elevator inspections are key to safer, more efficient operations and significant long-term cost reduction.

Your commitment to safety starts with proper upkeep. At Keystone Elevator, we’re ready to offer our expertise in elevator repairs 24/7. Contact us today and let’s ensure the lasting reliability of your elevators.

The Importance of 24-Hour Emergency Elevator Service

It’s everyone’s classic nightmare when stepping into an elevator: the doors close behind you, the elevator starts moving, and then it comes to a sudden stop between floors. What do you do?

Your property’s occupants should never have to ask themselves this question. Instead, they should be able to trust that help is on the way!

Having a 24/7 emergency elevator service on call allows you to protect your property and its visitors when time is of the essence. Here’s what you should know.

Common Causes of Elevator Emergencies

When you’re dealing with a malfunctioning elevator, countless culprits can come into play.

Material defects, worn parts, power outages, and mechanical failures can cause issues with an elevator. Natural disasters or building fires that wreak havoc on a property’s structure or electrical system can also cause failure. In some buildings, vandalism may be an issue, as users may pry open or break doors on their own.

These problems can make an elevator stop between floors, cause a door failure, or trap users within the structure. In the worst-case scenario, an elevator malfunction can cause serious injury or even death.

Benefits of 24/7 Emergency Elevator Service

If you own or manage a commercial property, routine elevator maintenance is crucial. These frequent inspections ensure that your business is following the proper safety code for elevators. They can also ensure that critical alarm components, including the emergency call button, function as needed if something goes wrong.

However, having an emergency elevator repair service on speed dial is crucial as well for several reasons:

Enhanced Safety

A faulty elevator can be dangerous. With emergency repairs, you can remove this danger from your building quickly, avoiding a lingering hazard.

Minimized Legal Risk

Building owners can minimize the risk of legal action with emergency services. These services free trapped users fast and with less risk of injury. If a lack of elevator service affects your ADA compliance, you may also be exposing your brand to further legal issues.

Reducing Downtime

Elevator failures can create unsafe conditions for your team. This can lead to downtime, which can lower productivity and increase your brand’s costs. Having an expert make emergency repairs right away can get the system up and running, allowing you to resume normal operations.

Expert Work

The right emergency elevator service team will boast experienced, licensed, and bonded contractors. These skilled workers can repair a wide range of elevator issues, providing superior repairs you can trust.

Enhanced Peace of Mind

These services are great for peace of mind if the worst should happen. Though it helps to ensure that users understand what to do in an emergency, both managers and occupants will feel more comfortable knowing there’s an expert on call, even after hours.

Trust Keystone Elevator With Your Repairs

No matter where your commercial elevator is located, getting swift repairs is crucial. Calling for 24/7 repair services can help you maintain your normal operations without risk to users, so make sure you have a reliable company on speed dial!

When you need emergency elevator service, we hope you’ll trust the experts at Keystone Elevator. Since 1995, we’ve been providing quality services throughout Massachusetts, Rhode Island, New Hampshire, and Maine. Contact us for fast and professional emergency services today.

The Ultimate Guide to Wheelchair Lift Inspections

Almost 132 million people across the globe require the use of a wheelchair for transportation. In the United States, there are an estimated 3.3 million regular wheelchair users.

People in wheelchairs rely on various equipment and infrastructure to get around. These include wheelchair lifts in homes and businesses. These require regular upkeep to ensure they are safe and in working order.

Below is the ultimate guide to wheelchair lift inspections. This article explains the importance of maintenance and repairs, including what you can expect from a technician. Keep reading to find out how to keep your business’s wheelchair lift in shape.

How Do Wheelchair Lifts Work?

Wheelchair lifts are most often used to move people up and down stairs. These might include stairways that are indoors or outdoors.

Like stair lift chairs, indoor lifts use a motor to move a platform up and down the stairs. These have platform handrails to help stabilize the rider.

Outdoor lifts are usually designed a bit differently. These comprise a box made up of a door, two stationary sides, and the end of the platform you wish to ascend (such as a patio or business entrance). The platform lift will move upwards until it is level with the upper surface.

Wheelchair lifts have different types of drive systems. Most are either electrical or hydraulic.

What Do Wheelchair Lift Inspections Entail?

Wheelchair lift inspections first involve looking for visible signs of rust or corrosion. Technicians will also look for signs of damage. While wear and tear are normal from extended use, catching minor issues before they become major ones is important.

Next, they will do a thorough examination of all the electrical components on the machine. This includes sensors that detect when an obstruction is in the path of the lift. This also includes the control system associated with the lift.

Technicians will also closely examine any moving parts on the device. These include gears and cables. They will apply lubrication if it is needed.

How Often Should You Have Wheelchair Lifts Inspected?

In general, you should have your wheelchair lift professionally inspected at least once every six months. This is a long enough duration that if components begin to wear out or minor issues occur, they will be caught before becoming dangerous.

However, you should also perform weekly tests to make sure the lift is safe for your employees. Check that the lift’s door will not open while in mid-air. You can also perform basic tests on the control system while no one is on the lift to ensure it works.

These tests can ensure the proper function of the machine and the safety of the rider. They also will help catch any issues that might arise between professional inspections.

Find Wheelchair Lift Servicing Companies Near You

Now that you understand the importance of wheelchair lift maintenance, you can be confident that yours works properly. Staying on top of inspections is a great way to ensure safety and prolong the lifespan of your equipment.

At Keystone Elevator Service and Modernization, we provide the highest quality “vertical transportation” solutions in the Boston metropolitan area. We offer commercial elevator repair and wheelchair lift maintenance. Contact us today for wheelchair lift inspections or other services.

Functionality and Aesthetics: Elevator Cab Design for Commercial Buildings

Every year, there are around 1.2 million elevators installed worldwide. Hundreds of people ride yours every week and the last thing you want is for your guests or clients to be uncomfortable.

The design and functionality of commercial buildings play a crucial role and creating a lasting impression on your visitors and occupants. There are a variety of elements that contribute to the overall ambiance and functionality of a commercial space.

A well-running and aesthetically pleasing elevator isn’t just a convenience, it’s also a reflection of your building’s identity in your brand’s commitment to excellence.

Creating an elevator cab design that is visually appealing can be challenging if you aren’t an expert. However, there’s no need to worry, as we are going to tell you everything you need to know in this guide.

Embrace Modern Minimalism

Less is more when it comes to an elevator cab design. A modern minimalistic design will exude a sense of sophistication and timelessness.

To create this look, you want to consider using a neutral color palette with clean lines. You should also incorporate simple materials such as stainless steel or gloss. This approach helps create an open in every field that makes an elevator cab seem more spacious and welcoming.

Lighting is Key

Lighting is a crucial component, no matter what type of elevator cab you have. It can help set the mood and will significantly impact the ambiance.

Think about the atmosphere that you want to create. Soft, warm lighting can be very welcoming, while bright lights may be preferred in a high-traffic area. You also have the option to customize your space with colored options to match your building’s overall aesthetic.

Invest in High-Quality Materials

When it comes to the design of an elevator cab, you’ll need to think about longevity and durability. Your elevator is going to get a lot of use and it needs to be able to withstand normal wear and tear.

Investing in high-quality materials not only ensures that your cab looks good but also reduces the cost of maintenance over time.

Focus on Accessibility

You may have a lot of elevator cab ideas, but don’t forget about accessibility. Not only is it a legal requirement, but it also reflects your commitment to inclusivity.

Features such as braille signage, ample space for wheelchairs, and mobility aids can show your guests that you care. This design Will show that your building is welcoming to everyone.

Riding in Style: Elevator Cab Design Tips

You have a lot to think about when it comes to the design of your commercial building. Your elevator cab design can easily slip your mind.

However, the appearance and functioning of the space is crucial and shouldn’t be ignored. By following the tips above, you can leave a lasting impression on your guests and elevate your building.

Our staff at Keystone Elevator are experts at designing the best elevator cabs. Send us a detailed message today, and will get back to you and answer all your questions about types of elevator cabs.

The Essential Guide to ADA-Compliant Elevators for Property Owners

The Americans with Disabilities Act (ADA) was endorsed in 1990. It made public places more accessible for people with disabilities. It covers a lot of different situations and has a big impact on building codes all over the country.

Elevators are among the most important parts of building codes that the ADA covers. If you’re building a new facility or remodeling an existing one, you’ll need to install ADA-compliant elevators that meet ADA elevator requirements.

Providing elevators for disabled people will help you ensure your building is compliant.

Are you concerned about meeting ADA elevator requirements? No need to worry. Check out these ADA elevator requirements.

Are ADA-Compliant Elevators Required?

There are buildings that may be exempt from some ADA requirements. Private buildings with fewer than three floors, or less than 3000 square feet per floor, are not required to include an ADA elevator.

Exceptions include shopping centers, a health care provider’s professional offices, or a public transportation facility/station. All other businesses built after 2010 must include an ADA elevator.

Owners of older buildings are required to comply with all ADA requirements. Otherwise, they risk being subject to liability lawsuits and federal fines.

Some businesses have reasons for not including an ADA elevator. They are still required to make “reasonable accommodations” for disabled individuals.

ADA Elevator Dimensions

When using an ADA-compliant elevator, the doors must stay open for at least three seconds. The elevator requirement gives people with disabilities enough time to get in and out safely.

ADA elevator dimensions must meet the ADA requirements. Doors must be 36 inches wide, so that wheelchairs can get in and out easily. The car depth is one inch.

The inside of a building elevator is 68 inches unless the ADA elevator has a center-opening door. In those models, the inside width must be 80 inches.

ADA Buttons and Signage

ADA elevator requirements are specific regarding elevator button designs and ADA signage.

Call buttons should be 0.75 inches big, so they’re easy to use. They should also be 42 inches above the floor.

Emergency controls are grouped at the bottom. Their centerlines are no more than 35 inches higher than the floor making it accessible so everyone can get to them in an emergency, regardless of their ability.

ADA signage is very important. Braille should be written on the control panel in textile letters, either right below the buttons or next to them. The numbers should be in ascending order to match the elevator.

There should also be a warning when the elevator reaches a certain floor. Buildings can use a green light or a recorded announcement.

Are You ADA-Compliant?

ADA-compliant elevators are designed to meet the needs of people with various disabilities.

Accessibility not only means being able to walk through the building but also being able to get out of the building in the event of an emergency. Whether someone is physically disabled, hearing, or visually impaired, using an elevator is a basic need.

Keystone Elevator Service & Modernization is available to inspect your elevators for ADA compliance. Contact us today to schedule an appointment.

Elevator Decommissioning: Why, When, and How

Elevator decommissioning is a complex job that requires specialists who understand the legal regulations associated with the process. Decommissioning and removing an unused elevator or model that’s in disrepair necessitates removing cabs, rails, wiring, the hydraulic system, and more. Keystone Elevator specializes in elevator services that include elevator decommissioning. We manage all the permitting that’s required by the Department of Public Safety as well as each aspect of the job, ensuring that your elevator’s decommissioning is compliant with safety laws. If you need your commercial elevator disconnected and removed, contact Keystone Elevator and let our elevator experts handle the job.

Why Does Your Business Need to Decommission Its Elevator?

Decommissioning an elevator refers to the regulated process of dismantling and removing an elevator and its parts. Businesses or organizations that wish to remove a commercial elevator must hire a licensed elevator service that specializes in elevator decommissioning and procure the proper permits for the job per legal requirements.

Commercial property owners might elect to remove an elevator from service for various reasons. The elevator may not be used enough to warrant its continued service. It might be old and in disrepair. Sometimes a property owner chooses to remove an elevator during remodeling projects or before installing a replacement elevator.

No matter the reason for removing your elevator, Keystone Elevator will properly dismantle and dispose of your elevator’s parts by the current legal code. Elevator decommissioning requires careful attention to regulations to ensure safety. We’ll manage all aspects of the decommissioning process, allowing customers to rest assured that their elevator’s removal is in safe, capable hands.

Elevator Decommissioning: Developing a Removal Plan

When your business contracts with Keystone Elevator for elevator decommissioning service, we’ll visit your premises to inspect your elevator and develop a plan for its decommissioning. Our specialists will carefully evaluate the job in association with proper procedures and elevator decommissioning regulations. After developing our plan, we’ll go over each detail with you and discuss the timeline and schedule for the job. If there are any special considerations or tasks, we can go over them before we begin the removal process.

Elevator Dismantling and Removal

The elevator dismantling and removal tasks are all part of proper commercial elevator decommissioning. Trust our elevator specialists to remove the car, rails, wiring, controllers, and other parts during the removal process. We also remove the hydraulic oil, oil lines, and tanks as part of our decommissioning service. All electrical and mechanical systems must be properly dismantled before they can be removed. We also your elevator’s doors as part of the decommissioning requirements to ensure public safety.

Customers trust Keystone Elevator for elevator decommissioning as well as elevator installation and repair. We have a reputation for providing elevator service to all types of businesses and organizations. If you need to remove an existing elevator from your premises, contact us to discuss our elevator decommissioning service.

What Actions to Take When Elevator Fault Codes Appear

Elevators are more than just a convenient way to get around your commercial building. If your structure is over two stories high, it’s likely a requirement for your building to be ADA-compliant.

Maintaining your elevator can help protect your investment, ensure ongoing ADA compliance, and help you pass the annual or biannual inspection required by the state of Massachusetts.

Even with regular maintenance, your elevator might still display a fault code from time to time. When this happens for the first time, you might be wondering how to handle it and what to do first. Keep reading as we explore what to do when elevator fault codes appear.

What to Do if Elevator Fault Codes Appear

When your fault monitor shows a code for the first time, you might have no idea how to handle it. However, ignoring that code can not only put users at risk but could also lead to a costly elevator violation for your business.

As soon as you notice something is wrong, use this elevator code checklist to get to the root of the problem.

Stay Calm

Noticing an error code on an elevator can be concerning. But it’s important to keep in mind that there are codes for a variety of different situations. Seeing an elevator fault code doesn’t necessarily mean that your elevator is at risk of a major malfunction.

The best thing that you can do when you see an elevator failure code is to remain calm. It’s a good idea to get everyone off the elevator and close it until you can get the code repaired.

The last thing you want to do is wait to address the problem. This can not only potentially put users in danger but could also lead to an elevator violation down the line.

Consult Your Manual.

When your elevator was installed, you should have received a manual. In this manual, you’ll find a list of all elevator fault codes.

Use this to diagnose what the fault code is about.

Schedule a Repair

The next step is to schedule an elevator repair. When you call your elevator repair specialist, you can provide them with the fault code and what the manual identifies it as. While they will do their own analysis when they arrive, having this information can help them better prepare for the repair.

Record the Repair and Code.

After the repair is completed, make sure to record the incident. Your business should have a log where all elevator repairs and incidents are recorded. Make a note of the date, what the fault code was, and the type of repair performed.

This information may help with future repairs if another fault code appears.

Maintaining Your Elevator

Seeing elevator fault codes for the first time can be scary and confusing. But using this elevator code checklist can help you get to the root of the problem quickly and allow you to get your elevator functioning again as soon as possible.

Scheduling regular preventive maintenance can help you reduce the frequency of fault codes. Check out the customized preventative maintenance programs to learn how Keystone can help you keep your elevators functioning properly year after year.

How Annual Elevator Inspection Services Enhance Your Riders’ Safety

Elevator inspection services are crucial for commercial properties in New England to ensure the safety of riders and comply with regulatory authorities. Improper facility management can lead to accidents or incidents, placing property managers at risk of legal responsibility for injuries or fatalities.

Annual Elevator Inspection Services

During annual elevator inspection services, certified professionals thoroughly examine elevator systems to ensure they are safe, comfortable, and efficient for all passengers. Regulatory authorities mandate these inspections, which are necessary for compliance with safety standards.

As a commercial property manager or facility manager in New England, you must have the elevators in your building inspected at least once every year. The interval between inspections varies based on the elevator use frequency, the manufacturer’s recommendations, and how often state and local regulations dictate.

Prioritizing rider safety is crucial for commercial property and facility managers as it impacts their reputation. A well-operating elevator that transports customers or clients in a safe and timely manner is good for business, and poor facility management can lead to accidents or incidents that can harm a company’s reputation.

In addition, failing to abide by elevator testing and inspection requirements set by regulatory authorities can have serious consequences, such as fines, passenger injuries, and other detrimental events.

The Benefits of Annual Elevator Inspection Services

Elevator inspections are crucial for ensuring the safety and longevity of elevator equipment. Here are some benefits of annual elevator inspection services:

Enhanced Rider Safety

Regular elevator inspections help identify potential safety hazards or malfunctions before they become major issues. Inspectors can detect issues such as worn sheaves, improper lubrication, and power failures. These issues can cause inconvenience, cost time and money, and even lead to injuries.

Elevator inspections can prevent breakdowns, minimize downtime, and increase productivity by detecting these issues early. The inspections also ensure that emergency response systems are functioning properly and that the overall safety of elevator equipment is maintained.

Compliance with Legal and Regulatory Requirements

As a commercial property manager, you are legally obligated to conduct annual elevator inspections to comply with government regulations. Failure to comply with these regulations can result in penalties and liabilities.

Elevator inspections can help maintain compliance and prevent legal issues by ensuring that elevator equipment adheres to specified codes and regulations. Inspections can also help identify deficiencies that can cause harm to users and require re-inspections to ensure the public’s safety.

Increased Longevity of Elevator Systems

Routine inspections and preventative maintenance are essential to identify minor issues and prevent them from escalating into major, costly repairs. While elevators are designed to offer 20-25 years of reliable service, constant usage, and evolving technologies necessitate eventual equipment upgrades.

Proactive maintenance and early detection can help avoid unexpected breakdowns and save money in the long run. A properly installed and regularly maintained elevator system will maximize your investment and property value, allowing you to execute any necessary modernization as a planned upgrade investment as opposed to an emergency expense.

Reputation Enhancement

Prioritizing rider safety through annual inspections can improve the reputation of commercial properties and facilities. Efficient elevators are crucial for maintaining building efficiency and tenant retention while increasing the value and market appeal of the property.

Bottom Line

Elevator inspections are crucial for ensuring the safety and efficiency of elevators. Regular inspections can help identify minor damages and prevent major faults from developing, which can compromise the safety of passengers.

If you are a New England commercial property or facility manager, it is crucial to prioritize elevator inspections to ensure the safety of your riders and comply with legal requirements. Contact Keystone Elevator Repair and Inspection service provider to schedule an inspection or for more information.

Which is Right for You Between Freight Elevator vs Passenger Elevator

Are you in the process of designing or renovating a building that requires an elevator? Choosing the right type of elevator is vital for the safety and efficiency of your property’s operations. This guide discusses freight elevators vs passenger elevators to help you pick the appropriate choice for your building. Read on!

Freight Elevator Vs Passenger Elevator

Freight elevators are designed for transporting heavy or bulky items. They’re ideal for buildings requiring frequent good transportation, such as warehouses, factories, or hospitals. Typically, freight elevators are larger and can hold much more weight than passenger elevators. They’re equipped with loading and unloading mechanisms, such as rolling or hinged doors, to facilitate the movement of goods.

Passenger elevators are intended for transporting people between floors. They’re smaller than freight elevators. Passenger elevators can be found in various buildings, including residential complexes, shopping centers and skyscrapers. These elevators come in multiple designs, from basic models to high-speed and custom-built elevators with luxurious interiors.

Differences Between Freight and Passenger Elevators

When selecting an elevator for your building, you must understand the key distinctions, including:

Size and Capacity

Freight elevators are larger and have higher weight capacities than passenger elevators. A typical freight elevator has a capacity of up to 9,000 pounds or more. Passenger elevators are generally smaller and have less weight capacity than freight elevators.

Loading and Unloading Mechanisms

Freight elevators come with loading and unloading mechanisms, such as rolling or hinged doors, to facilitate the movement of goods. These doors are usually larger and sturdier than those in passenger elevators, making it easier to move bulky items. Passenger elevators have standard doors designed for the safe and easy entry and exit of people.

Speed and Operation

Freight elevators operate slower than passenger elevators due to their larger size and weight capacity. They have more robust operating systems, such as motor generators or hydraulic systems, to handle heavy loads. Passenger elevators come in various speeds, from standard to high-speed models that you can choose based on your needs.

Both freight and passenger elevators have various safety features for safe operation. However, freight elevators have additional safety features, such as emergency stop buttons, overspeed governors, and interlocks to prevent them from moving unless the doors are fully closed.

Which Type of Elevator Should You Choose?

The answer largely depends on your building’s needs. If your building requires frequent transportation of goods, a freight elevator may be the best option. If your building is intended for people, you must provide comfortable and efficient transportation, and a passenger elevator is the way to go. Here are factors to consider:

Building type and usage: A commercial building housing several businesses might require a larger freight elevator to handle the transportation of goods.

Type of goods for transportation: Heavy or bulky goods require a larger and more robust freight elevator, while a passenger elevator is suitable for lighter goods.

Frequency of use: If your building has frequent elevator use, you might need a more durable and reliable elevator, such as a freight elevator.

Choose an Appropriate Elevator for Your Building

Selecting the right elevator will enhance efficiency, safety, and accessibility in your building. Evaluate your building’s needs, and choose an elevator that best offers optimal performance. At Keystone, we’re here to help with your elevator needs. Contact us today, and we’ll be glad to guide you accordingly.

How Elevator Modernization Can Save Your Commercial Property Time and Money

Outdated commercial elevators can use as much energy in a year as a household in four months. That’s a significant energy cost for property owners and managers. Especially when such elevator systems are prone to breakdowns and safety hazards.

But elevator modernization can remedy these problems. Upgrading your elevators reduces energy consumption to save time and money in the long run. Modernization also increases your commercial property value, securing your investment for the future.

This article details the benefits of elevator modernization in commercial buildings. Read on to discover how elevator modernization can help your property today.

Improved Safety and Reliability

Outdated elevator systems are prone to breakdowns. Breakdowns don’t just lead to downtime and loss of productivity. They also pose safety hazards for passengers.

Modernizing elevators can address these issues by upgrading critical components in most types of elevators:

- Control systems

- Motors

- Doors

- Hydraulics

Updating these elevator requirements reduces the number of breakdowns. Fewer breakdowns mean fewer accidents. Thus, you can mitigate regular maintenance prices and ensure safety.

Enhanced Energy Efficiency

Elevators can consume a large amount of energy in commercial buildings. However, updated elevators often use advanced energy-efficient tech. This includes the following:

Regenerative Drives

Regenerative drives capture energy produced during braking. Then, they feed it back into the building’s electrical grid. This kind of energy recycling helps cut costs and energy consumption at your commercial property.

LED Lighting

Modern elevators often use energy-efficient LED lighting instead of incandescent bulbs. LED lights use less energy and last longer than classic bulbs. So, making the switch cuts maintenance costs and energy use.

Sleep Mode

The sleep mode feature of modern elevators is a game-changer for energy savings. Sleep mode can sense when the elevator is not in use. It shuts down the elevator’s interior lighting and ventilation systems during those times.

Elevator modernization via sleep mode helps cut energy bills during low-traffic periods. If no one uses your commercial elevator, it isn’t consuming energy.

Variable Frequency Drives

Variable frequency drives (VFDs) help reduce energy consumption by controlling motor speed.

Traditional elevator systems use a fixed-speed motor. This means the engine always uses the same energy to move the elevator, regardless of the load.

In contrast, elevators equipped with VFDs can vary the speed of the motor. With VFDs, the rate varies depending on the weight of the elevator car, including riders.

When the elevator car has a light load, the VFD can slow down the motor, reducing the energy needed to move the car. When the car has a heavy load, the VFD can speed up the engine to compensate for the additional weight.

By honing the elevator speed to match the load, VFDs reduce the energy needed to use the elevator. VFD-equipped elevators can reduce energy consumption by 70% compared to traditional systems.

Increased Property Value

Upgrading your elevator system can increase the value of your property. Modern elevators enhance the aesthetic appeal of the building. But they also provide better functionality and accessibility.

These features are attractive when the time comes to sell. Buyers may pay more for buildings that already have aesthetic and accessibility features. That way, they don’t have to make these upgrades on their dime.

Elevator Modernization Near Me: Trust the Experts

Elevator modernization is a smart investment for commercial buildings. New elevator technology helps building owners and managers save time and money. It also improves the safety and efficiency of commercial elevators.

At Keystone Elevator, we specialize in top-quality elevator upgrades for commercial property owners. Whether you’re on a budget or have a complex project, there isn’t anything our team can’t handle. Our experienced technicians and engineers can find a solution for your needs.

If you need elevator modernization, Keystone Elevator is here to help. Contact us today to learn more about our services.